Table of Contents

ToggleIntroduction: Why the Right Pickling Jar Matters

If you are in the food business, you know that the container is just as important as the recipe. You can have the crispest cucumbers and the perfect brine ratio, but if the packaging fails, the product fails. For food factories and bulk buyers, the pickle jars aren’t just a vessel; they’re a tool for preservation and a billboard for your brand.

At Smilebottles, we work with manufacturers every day who are trying to solve a specific problem: how to keep food fresh while making it look irresistible on the shelf. Whether you are producing a high-end artisanal jar of pickles or running a high-speed line for mass retail, the glass you choose dictates your production speed, breakage rates, and shelf life.

This guide is going to look at how to select the right glass jars for pickling from a manufacturing and retail perspective. We will cover everything from the standard 16 oz retail jar to the massive 5 gallon pickle jar found in commercial kitchens, ensuring you have the right information to make a smart purchasing decision.

What Makes a Good Pickling Jar?

Plastic has its usages, but in the world of acidic foods, glass is the undisputed king. When you are dealing with vinegar, salt, and fermentation gases, you need a material that is stubborn—it shouldn’t react to anything.

Why Glass Is Ideal for Pickling

The chemistry of pickling is aggressive. High acidity can break down lesser materials, leaching chemicals or altering flavors. A glass pickle jar is chemically inert. It locks the flavor in and keeps contaminants out.

Key Characteristics of Quality Pickling Jars

When you are sourcing pickling jars for a production line, you need to look at three technical specs:

1 Thermal Shock Resistance: If you are hot-filling your jars, the glass needs to handle the temperature spike without cracking.

2 Neck Finish: The threading on a picking jar (a common term for jars used during harvest season) needs to be precise. If the finish is uneven, your capping machine will jam, or the vacuum seal will fail.

3 Base Thickness: A big pickle jar holds a lot of weight. If the base is too thin, it will shatter during palletization or shipping.

Different Types of Pickling Jars

Mason Jars (Ball / Kerr Style)

The mason jar is iconic. While the two-piece lid system is mostly for home use, commercial mason jars for picking use a single-piece “lug” cap that mimics that classic look.

The Vibe: Authentic, homestyle, traditional.

The Function: Excellent for high-speed filling lines. The shoulders of the jar protect the seal.

Best Application: Sliced bread-and-butter pickles, relish, and premium sauces.

Glass Jars with Clamp / Clip-Top Lids

They are often called “Kilner” or “Fido” style; these feature a heavy glass lid, a rubber gasket, and a wire bail.

The Vibe: Premium, European, reusable.

The Function: These are often used for fermentation because the rubber gasket can allow excess gas to escape without letting air in (burping).

Best Application: Sauerkraut, kimchi, or high-ticket gift items. Note: These are harder to cap automatically and often require semi-manual labor on the line.

Ceramic Crocks vs. Glass Jars

You might see the occasional Chinese pickle jar made of ceramic with a water moat rim for sealing. These are beautiful and traditional for fermentation. However, in a retail environment, customers want to see the product. We often manufacture a glass pickle jar that mimics the shape of these traditional crocks but offers the visibility of clear glass. It’s a modern twist on a classic design.

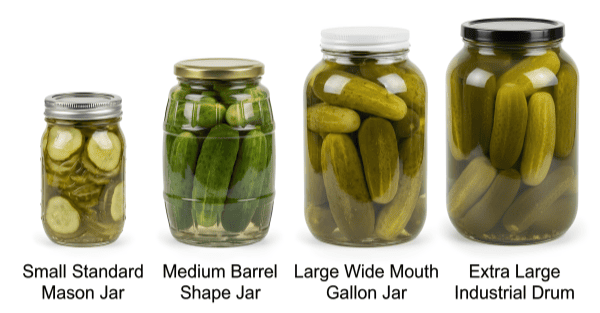

Vintage and Barrel Shapes

Nostalgia sells. Many brands try to replicate the look of a vintage Vlasic pickle jars that stout, barrel-like shape that implies a crunchy, hearty pickle. Using a custom mold to create a barrel or “drum” shape can help your product stand out in a sea of straight-walled jars.

How to Choose the Right Glass Jars for Pickle Packaging

One size does not fit all. Your choice of jar should depend on where your product is being sold—is it a boutique shop, a supermarket, or a restaurant supplier?

Size Matters: Retail vs. Food Service

Retail Standard (16oz – 32oz): This is your standard fridge door size. A 32oz glass pickle jar is the volume driver for whole dills.

Club Store Size (64oz / Half Gallon): Families buy these. It’s a big pickle jar that suggests value.

Food Service (1 Gallon):1 gallon pickle jar is the backbone of the deli industry. These need to be sturdy and have wide mouths for quick access during a lunch rush.

Bulk/Industrial (2 Gallon – 5 Gallon): The 5 gallon pickle jar is a beast. You usually see these in movie theaters, concessions, or wholesale manufacturing. It is essentially the biggest jar of pickles you can transport safely.

Occasionally, you might see a giant jar of pickles on a counter display—these are often custom marketing tools rather than high-volume sellers.

Wide Mouth vs. Narrow Mouth

If you are packing whole cucumbers, you need a wide mouth (82mm or larger). Trying to force a whole vegetable into a narrow opening damages the product and slows down the filling line. Narrow mouths are strictly for liquids, spears, or small items like capers.

Airtight is Alright

The seal is the finish line. For pickle jars, we recommend Twist-Off (Lug) finishes for automated lines. They are secure, easy to apply, and familiar to the customer.

Pickling Essentials: What Fits Where?

For Classic Vegetables

For dill spears or carrots, you want height. A tall, cylindrical glass pickle jar allows you to pack the spears vertically. This looks organized and prevents the vegetables from crushing each other.

For Larger Vegetables & Bulk Pickling

If you are pickling whole cabbage heads, peppers, or doing a pub style mixed pickle (sometimes referred to in niche markets as a pickle jar Falmouth style, referencing traditional English deli counters), you need width. A squat, wide, large pickle jar allows for hand-packing of irregular shapes.

For Exotic & Fruity Pickles

Pickled mango, peaches, or watermelon rinds are visually stunning. Don’t hide them. Use a “globe” shaped jar or an “Orcio” jar. These curved shapes magnify the contents, making the fruit look juicy and full.

For Fermentation Projects

If you are selling a live product (unpasteurized), you have to manage gas. A standard tight seal might cause the jar to burst. In this case, a clamp-top pickle jar is superior, or you need a specialized vented induction liner.

For Quick Pickling & Small Batches

Small glass jars (8oz or 12oz) are perfect for fridge pickles or test batches. They encourage impulse buys at checkout counters.

Pickling Jars Comparison Table

Here is a quick reference for bulk buyers to match the jar to the job.

Jar Style | Best For | Seal Type | Durability |

Mason / Utility | Standard Dills, Relish | Lug / 2-Piece | High |

Barrel Shape | Whole Pickles, Nostalgia | Twist-Off | High |

Clamp-Top | Fermented Foods, Gifts | Rubber Gasket | Moderate |

Wide Mouth Gallon | 1 gallon pickle jar for Delis | Twist-Off | Very High |

Industrial Drum | 5 gallon pickle jar for Bulk | Screw Top | High |

How to Select the Right Sealing Method for Glass Jars

A huge frustration for consumers is figuring out how to open a pickle jar that is vacuum-sealed too tightly. While a tight seal is necessary for safety, it shouldn’t require power tools to open.

Common Sealing Options

Lug Caps (Twist-off): The metal claws grip the glass threads. Easy to open with a “pop.”

CT (Continuous Thread): A long screw thread. Provides a very secure seal but can be difficult to open if sticky brine gets into the threads.

Key Features to Look For

To avoid the stuck lid complaint, look for caps with a knurled edge for better grip. Also, ensure your liner material (usually Plastisol) is formulated for acid resistance. If the vinegar corrodes the underside of the lid, it increases friction, making it impossible to open.

Key Pickling Steps & Best Practices (For Factories)

As a glass manufacturer, we see where lines go wrong. Here are tips to ensure our jars perform well on your line.

Sterilization: You must wash and heat the glass jars before filling.

Lids & Seals: The pop button on the lid is your safety guarantee. Ensure your capping machine is set to the correct torque. Too loose, and the vacuum fails. Too tight, and the customer can’t open it.

Vinegar Choice and Glass Interaction: Glass is non-reactive, which means you can use any vinegar concentration (5% is standard). Unlike metal or plastic, you don’t need to worry about the container degrading over the years of storage.

Headspace: Leave about 1/2 inch of space at the top. This allows the liquid to expand during processing and creates a vacuum as it cools. Without headspace, the pickle jars with lids won’t seal properly.

Produce Quality: A big jar of pickle spears looks great, but if the cucumbers were old, they will float or shrivel. Glass magnifies imperfections, so quality control on the produce is vital.

Safety First: Check your glass handling. Metal-on-glass contact (like filling nozzles hitting the rim) can cause checks or micro-cracks. These can lead to breakage later in the consumer’s hands.

Label Everything: On a round glass pickle jar, the label application can be tricky. Ensure your label adhesive is water-resistant (for condensation) and that your labeler is calibrated to the jar’s curvature.

Check for Spoilage: Before you ship pallets to retailers, do a vacuum check. Any lid that clicks when pressed is a seal failure.

Storage Tips: Advise your retailers to keep the product out of direct sunlight. While glass protects the flavor, UV light can turn vibrant green pickles into a dull olive color.

Why Choose Quality Glass Pickling Jars from a Trusted Manufacturer

If you are scaling up production, you can’t rely on random suppliers. You need a partner.

At Smilebottles, we understand the food industry.

Customization: We can emboss your logo on the glass pickle jars, giving you that premium feel with modern durability.

Consistency: Our molds are precision-engineered. Every picking jar is identical.

Variety: We stock everything from the tiny sampler to the giant jar of pickles for your marketing displays.

Supply Chain: We handle the logistics of moving heavy glass, ensuring it arrives at your factory ready to fill.

Frequently Asked Questions (FAQ)

Here are the questions we hear most often from our B2B clients.

1 Q: Are glass jars safe for commercial fermentation?

1 A: Yes, they are the best option. You just need to choose the right lid. For active fermentation, use a clamp-top or a specialized vented lid. For finished pickles, a standard lug cap is perfect.

2 Q: Can I get a custom mold made?

2 A: Yes. If you want a unique shape—like a chinese pickle jar silhouette or a square jar for efficient packing—we can create a custom mold for your brand.

3 Q: What is the largest jar you sell?

3 A: For standard production, the 5 gallon pickle jar is the max. It’s heavy and requires careful handling.

4 Q: Why do customers search for Pickle Jar Falmouth?

4 A: This usually refers to a specific traditional or “pub style” aesthetic popular in certain regions. We offer classic jars that fit this “gastropub” look perfectly.

5 Q: Do you sell the lids too?

5 A: Yes, we provide the full package—pickle jars with lids. We ensure the cap fits the glass finish perfectly to prevent leaks.

6 Q: Is a 1 gallon pickle jar too big for retail?**

6 A: Generally, yes. It’s too tall for home shelves. But for warehouse clubs (like Costco) or food service, it is a standard seller.

7 Q: How do I stop lids from rusting?**

7 A: This is a common issue with cheap lids. Ensure you order lids with an acid-resistant coating on the *inside* and *outside*. The brine vapor is corrosive.

Conclusion

Choosing the right packaging is about balancing aesthetics, function, and cost. Whether you need a truckload of standard mason jars for picking or a custom run of a big pickle jar design, Smilebottles has the expertise to support your production line. Let’s make your product look as good as it tastes.