Table of Contents

ToggleAuthor: SmileBottles Editorial Team

Estimated Reading Time: About 15 Minutes

As a business owner, procurement manager, or retailer, the packaging you choose is the physical handshake between your brand and your customer. Whether you are bottling premium spirits, essential oils, beverages, or cosmetics, the quality of your glass container speaks volumes. But have you ever stopped to consider the journey of that bottle? Understanding the glass bottle manufacturing process is not just interesting trivia—it is a strategic advantage for your business.

At Smilebottles, we believe that an educated buyer is our best partner. When you understand how glass is made step by step, you can better evaluate quality, anticipate lead times, and communicate effectively with your custom glass bottle manufacturer. In this guide, we are going to take you behind the scenes of the factory floor. We will explore how glass is manufactured, from the raw minerals in the earth to the finished pallet in your warehouse. By the end of this article, you will know exactly how to choose the right wholesale glass bottles for your specific needs.

The Recipe: What Is Glass Made Of?

Before we discuss the machinery, we must discuss chemistry. To the naked eye, glass looks like a single, uniform material. In reality, it is a complex fusion of minerals. So, what is the main ingredient in glass?

The Foundation: Silica Sand

The primary structural component of all commercial glass is silica sand for glass making (Silicon Dioxide). If you have ever wondered how is glass made from sand, it is because silica acts as the glass former. It provides the bottle with its hardness, clarity, and structural integrity. However, pure silica requires incredibly high temperatures to melt—far too high for efficient mass production. This brings us to the modifiers.

The Flux and Stabilizers

To make glass production feasible, we must lower the melting point of the sand. We do this by adding Soda Ash (Sodium Carbonate). This acts as a flux. However, if we only used sand and soda, we would create “water glass,” which would eventually dissolve when filled with liquid. That would be a disaster for your beverage product!

To prevent this, we add Limestone (Calcium Carbonate). This acts as a stabilizer, making the glass durable and water-insoluble. This combination is how glass is made up of a structure that is chemically resistant and strong.

Soda Lime Glass Composition

The vast majority of bottles you buy from a glass bottle supplier are made of “Soda-Lime Glass.” If you were to analyze the ingredients in glass used for bottles, the recipe typically looks like this:

70-75% Silica Sand, 12-16% Soda Ash, 10-15% Lime (Calcium Oxide)

Small percentages of other additives for refining or color.

So, glass is made from what material? It is a blend of sand, soda, lime, and recycled glass.

The Sustainability Hero: Cullet

A massive part of modern glass manufacturing steps involves “Cullet.” Cullet is simply recycled, broken glass. What is used for making glass in a sustainable factory? A large percentage is cullet. It melts at a lower temperature than raw materials, which reduces energy consumption and extends the life of the furnace. This is how glass is obtained in a way that supports the circular economy.

Step-by-Step: How Glass Bottles Are Made

Reading about the process is one thing, but seeing it in action is where you truly understand the engineering behind your packaging. At Smilebottles, our floor is a mix of intense heat, precise timing, and heavy machinery. Here is exactly how glass is made step by step, taking you from a pile of raw minerals to the finished containers ready for your filling line.

Step 1 — Select & Test Raw Materials

Great bottles start with great ingredients. Before we even light the furnace, we have to verify the purity of the raw materials for glass production. We run quality checks on the silica sand, soda ash, and limestone to ensure they are free from moisture and contaminants. Even a tiny amount of iron in the sand can ruin a batch of clear flint glass by turning it green.

We also process “Cullet” (recycled glass). This involves sorting and cleaning the crushed glass to strip away any ceramics, stones, or metals. If a piece of ceramic gets into the melt, it doesn’t dissolve; it creates a “stone” defect that weakens the bottle wall. Clean glass raw materials are the first and most important step in quality control.

Step 2 — Batch Preparation (Weighing + Mixing)

Once the materials pass inspection, they move to the batch house. Here, giant electronic scales weigh the ingredients down to the gram. The specific “recipe” changes depending on whether we are making amber beer bottles, clear spirit bottles, or cosmetic jars.

Everything is then mixed into a single, consistent blend. This consistency is vital. If the batch isn’t mixed perfectly, the glass melting process will be uneven, leading to streaks or bubbles in the final product. This prepared mixture is now ready to become molten glass.

Step 3 — Melting (Turning Batch Into Molten Glass)

The batch is fed, or “charged,” into the furnace 24 hours a day. You might be wondering, what temperature does glass melt? To fuse these minerals together, our furnaces run at scorching temperatures between 1500°C and 1700°C.

Inside the furnace, the solid materials undergo a chemical reaction. The sand dissolves, the soda ash helps it melt, and the limestone stabilizes the mixture. This is the core of how glass is produced—turning a gritty powder into a smooth, glowing orange liquid. Precise temperature control is critical here; a shift of even a few degrees can change the glass’s viscosity and ruin the entire production run.

Step 4 — Refining / Fining (Removing Bubbles & Impurities)

Freshly melted glass is full of trapped gases and tiny air pockets we call “seeds.” If we formed the bottle right now, it would look speckled and be structurally weak. To fix this, the glass goes through “refining.”

We add fining agents and raise the temperature slightly. This forces the bubbles to rise to the surface and escape, much like carbonation leaving a soda. This step ensures that how clear glass is made meets the high aesthetic standards required for premium brands.

Step 5 — Conditioning (Preparing Glass for Forming)

Once refined, the glass is actually too hot and runny to shape. It flows from the furnace into a channel called the “Forehearth.” Here, we gently cool the glass down to a “working temperature” (usually around 1100°C to 1200°C).

This process is called conditioning. We need the glass to be the consistency of thick honey. If the molten glass is too hot, the bottle won’t hold its shape; if it’s too cool, it won’t fill the mold details. Getting this viscosity right is the key to consistent forming.

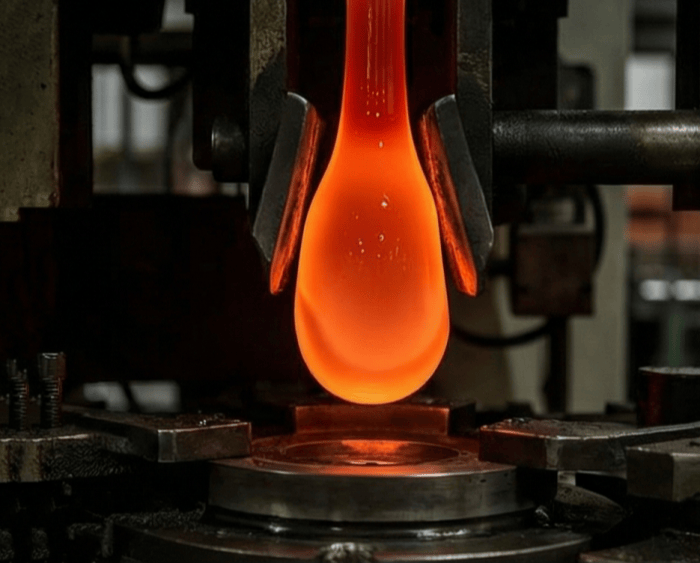

Step 6 — Moulding & Forming (Shaping the Bottle)

This is the heart of the glass bottle manufacturing process. A mechanical blade shears the stream of glass into precise cylindrical lumps called “gobs.” Gravity drops the gob into the glass forming machine (typically an I.S. Machine).

We use a two-stage forming concept to ensure the wall thickness is even:

Blank Mold: The gob drops into the first mold to create a “parison” (a pre-form). This forms the neck finish first.

Final Mold: The parison is flipped into the second mold and blown out to the final bottle shape.

Depending on your design, we use specific glass manufacturing methods:

Blow-and-Blow: Compressed air forms the parison. This is standard for narrow-neck bottles like wine or beer.

Press-and-Blow: A metal plunger pushes into the glass to form the parison. This is used for wide-mouth jars and allows for better weight distribution (lightweighting).

Step 7 — Annealing (Eliminating Internal Stresses)

When the bottle leaves the mold, it is red-hot (around 600°C). If it cools down rapidly in the open air, the outer surface cools faster than the core, creating tension that will cause the bottle to shatter.

To prevent this, bottles travel through an “Annealing Lehr.” This is a long tunnel oven that reheats the bottles to a uniform temperature and then cools them down very slowly over 30 to 90 minutes. This controlled cooling curve relieves internal stress. Annealing is non-negotiable; without it, the bottle would be too fragile for filling or shipping.

Step 8 — Surface Treatments (Optional but Common in Industry)

Glass-on-glass contact creates friction. If bottles rub against each other on a high-speed line, they can scratch (scuff) or even break. To prevent this, we usually apply two coatings:

Hot-End Coating: A thin layer of tin oxide is applied before the annealing lehr to strengthen the glass surface.

Cold-End Coating: A layer of polyethylene wax is sprayed after the lehr.

This makes the bottles slippery (lubricity), allowing them to glide against each other smoothly. This is a vital step in how glass bottles are manufactured for automated filling plants.

Step 9 — Inspection & Quality Control

Before packing, every single bottle has to pass the quality control checkpoint. We use a mix of automated technology and human expertise.

Visual Inspection: High-speed cameras rotate the bottle to scan for aesthetic defects like bubbles, stones, blisters, or scuffs.

Dimensional Checks: Sensors measure the height, diameter, and verticality. Most importantly, we check the “neck finish” (bore and thread) to ensure your cap will seal perfectly.

Performance Tests: We pull random samples for destructive testing. We check internal pressure limits (for carbonated drinks), thermal shock resistance, and impact strength.

This rigorous inspection is how glass mass produced at Smilebottles maintains a defect rate near zero.

Step 10 — Packing, Palletizing & Shipping

The final step in the process to make glass market-ready is packaging. Automated palletizers stack the bottles layer by layer. We insert divider sheets (tier sheets) between the rows to prevent contact damage.

For wholesale glass bottles destined for export, we use heavy-duty shrink wrap and strapping to immobilize the load. Each pallet is labeled with a batch and lot number, providing full traceability. This ensures that when your bulk glass bottles arrive, they are clean, organized, and ready for your production line.

Quality Control: Ensuring Perfection

As a buyer of bulk glass bottles, you cannot afford breakage or defects. How is glass mass produced without errors? Through rigorous automated and manual inspection.

At Smilebottles, our inspection line checks for:

Dimensional Accuracy: We use cameras to measure the height, diameter, and most importantly, the neck finish. If the neck is off, your cap won’t seal.

Visual Defects: We scan for “stones” (unmelted raw material), “seeds” (bubbles), or “checks” (tiny cracks).

Stress Testing: We perform squeeze tests and internal pressure tests.

Only after passing these tests are the bottles palletized. This is how glass manufactured at a high standard reaches your warehouse safely.

Beyond the Standard: Different Types of Glass

While soda lime glass composition is the industry standard for bottles, you may encounter other terms during your product research. It is helpful to understand the broader glass making industry.

How Is Crystal Glass Made?

If you are looking for premium decanters or high-end perfume bottles, you might ask about crystal. While standard glass uses lime, crystal traditionally used lead oxide (though modern “lead-free crystal” often uses barium or zinc). These heavy elements increase the refractive index, making the glass sparkle. How is glassware made with crystal differs slightly in the cooling phase, as the material is denser.

How Is Sheet Glass Made?

It is worth noting that the process of making glass windowsis fundamentally different from that of making bottles. Window glass is made using the “Float Process.” Molten glass floats on a bath of molten tin to create a perfectly flat surface. This fabrication of glass is distinct from the molding process used for containers.

How Is Natural Glass Formed?

Interestingly, how glass was made originally wasn’t by human hands at all. How is glass made in nature? It occurs when volcanic lava with high silica content cools rapidly, preventing crystallization. This creates Obsidian. While you cannot order custom glass bottle manufacturer services for obsidian, it is the ancient ancestor of the manufactured glass we use today.

Sustainability: Glass Is Made From Recyclability

One of the biggest selling points of things made by glass is sustainability. Glass is made from what? Ideally, it is made from itself.

Closed Loop: Old bottles can be crushed and turn into glass again infinitely without losing quality.

Energy Efficiency: Using cullet in the glass manufacturing raw materials mix reduces the melting temperature.

Consumer Preference: Modern consumers prefer manufactured glass over plastic due to its eco-friendly nature and lack of chemical leaching.

When you buy from a responsible glass bottle manufacturer, you are participating in a green supply chain.

How to Choose the Right Bottle for Your Brand

Now that you understand how glass is manufactured, how do you apply this knowledge to your purchasing strategy? Here is a guide to navigating the manufacturing of glass options.

1. Customization and Molds

If you want your brand to stand out, a stock bottle might not be enough. How to produce glass with a custom design involves creating a new set of iron molds.

Design: We create a 3D rendering of your concept.

Mold Casting: We produce the blank molds, final molds, and neck rings.

Sample Run: We produce a small batch to test the glass forming dynamics.

Mass Production: Once approved, we move to full production.

2. Choosing the Right Glass Color

The raw materials glass recipe can be tweaked to change the color. This is how glass is created with functional properties:

Amber Glass: Iron, sulfur, and carbon are added. This blocks UV light, making it essential for beer and certain pharmaceuticals.

Green Glass: Chrome Oxide is added. This is the classic choice for wine.

Flint (Clear) Glass: Decolorizing agents like Selenium are used to make the glass ultra-clear. This is ideal for spirits and water where you want to show off the product inside.

3. Specialty Shapes

The glass fabrication process is versatile. By changing the molds on the I.S. machine, we can switch from standard bottles to specialty items. Whether you need a heavy-base jigger shot glass, a laboratory-style bologna bottle, or distinct vasos para shots for a tequila brand, the underlying physics of how do glass made items remain the same, but the tooling changes.

Why Choose Smilebottles?

Understanding how the glass made its way from a pile of sand to a premium container helps you appreciate the value it adds to your product. It is a process of intense heat, precise chemistry, and rigorous engineering.

At Smilebottles, we are more than just a vendor; we are experts in the manufacturing process for glass. We control the process to make glass consistent, strong, and beautiful.

We know what makes glass flawless.

We understand how glass is made with the right chemical balance for durability.

We master how to make glass bottles that run smoothly on your filling line.

Stop wondering how to make glass work for my brand. Let us handle the glass production for you.

How to get glass that fits your budget and brand vision? It starts with a conversation. Contact Smilebottles today for a quote on your glass bottle manufacturing needs. Let’s create something clear, strong, and beautiful together.

FAQ Frequently Asked Questions About Glass

We often hear these specific questions from our clients regarding the glass industry process.

Q1:How can you make glass at home?

A1:We often see searches for how to make glass at home. While you can melt sugar to make “candy glass,” true glass making requires dangerous temperatures (1500°C+). It is not safe or practical for a DIY project. How do u make glass safely? You leave it to the professionals with industrial furnaces!

Q2:Where does glass come from originally?

A2:How was glass invented? Legend says Phoenician sailors discovered how to make glass from sand when their cooking fires melted sand on a beach. However, historians believe the Egyptians were the first to master the process of making glass vessels. Today, where is glass made? It is a global industry, but China is a leading hub for glass product manufacturing due to advanced technology and access to the ingredients in glass.

Q3:What material is glass made of exactly?

A3:To summarize what is glass composed of: It is an inorganic, non-metallic solid. It is made from glass formers (silica), fluxes (soda ash), and stabilizers (limestone).

Q4:How are drinking glasses made versus bottles?

A4:The process is similar, but drinking glasses (glassware) are often made using a press machine or spinning process rather than the “Blow and Blow” method used for bottles. However, the glass melting process is identical.

Q5:How are wine glasses made with thin stems?

A5:High-end wine glasses are often pulled or drawn to create the stem, or the stem is pressed separately and fused to the bowl. This requires a different setup than the standard glass bottle production process.

Final Thoughts

Glass bottle production is a precise process, from raw material selection to melting, forming, annealing, inspection, and packing. When you understand these steps, you can choose stronger, safer, and more reliable bottles for your brand. With Smilebottles, you get stable quality control and reliable supply for your brand’s bulk orders.