In the world of packaging, how glass bottles are designed, especially their lids, significantly impacts how a product stands out and satisfies customers. For those in the wholesale and retail sector, getting to grips with the subtle details of glass bottleneck finishes can set you apart from the competition. This blog is set to explore why neck finishes are so crucial in the wholesale glass bottles market and the effect they have on the range of products you offer. By understanding these intricacies, you can better cater to your customers’ needs and preferences, enhancing your product’s appeal and functionality.

Section 1 What is a Neck Finish?

Glass bottleneck finishes refer to the specific design and threading at the opening of a glass bottle or jar. Determining how it will be sealed and what type of closure it can accommodate. This aspect of bottle design is crucial for ensuring the product inside is kept secure, fresh, and free from contamination. The neck finish includes the size, style, and threading pattern, which must match the closure mechanism. Whether that’s a screw cap, cork, stopper, or any other type of lid—to function correctly.

Neck finishes are standardized to some extent, with specific types and dimensions categorized by codes such as GPI (Glass Packaging Institute) in the United States or the European equivalent, to ensure compatibility between bottles and closures from different manufacturers. These codes describe the diameter, thread style, and number of threads per inch. Helping suppliers and manufacturers select the right cap or closure for their products.

The choice of neck finish affects not only the functionality and seal quality of the bottle but also its aesthetic appeal. Certain neck finishes are preferred for specific industries or products. For example, a cork finish might be chosen for wine bottles for its traditional appearance and functionality, while a screw cap could be selected for its convenience and tight seal in food and beverage products. Understanding neck finishes is essential for anyone in the business of packaging and selling products in glass bottles or jars, as it impacts both the product’s integrity and consumer experience.

Section 2 Types of Neck Finishes

Expanding on the types of neck finishes to provide a more enriched understanding, let’s delve deeper into the nuances of each finish type:

▶ Screw Cap Finish

The screw cap finish is a versatile option. It’s ideal for a broad array of products ranging from beverage bottles to personal care items. Its design features a threaded neck that pairs with a matching threaded cap, ensuring a tight and secure closure. This type of finish is celebrated for its ease of use, allowing for convenient opening and resealing, which is a significant advantage in consumer products. Screw caps are also highly customizable, with options for tamper-evident features, and child resistance.

▶ Cork Finish

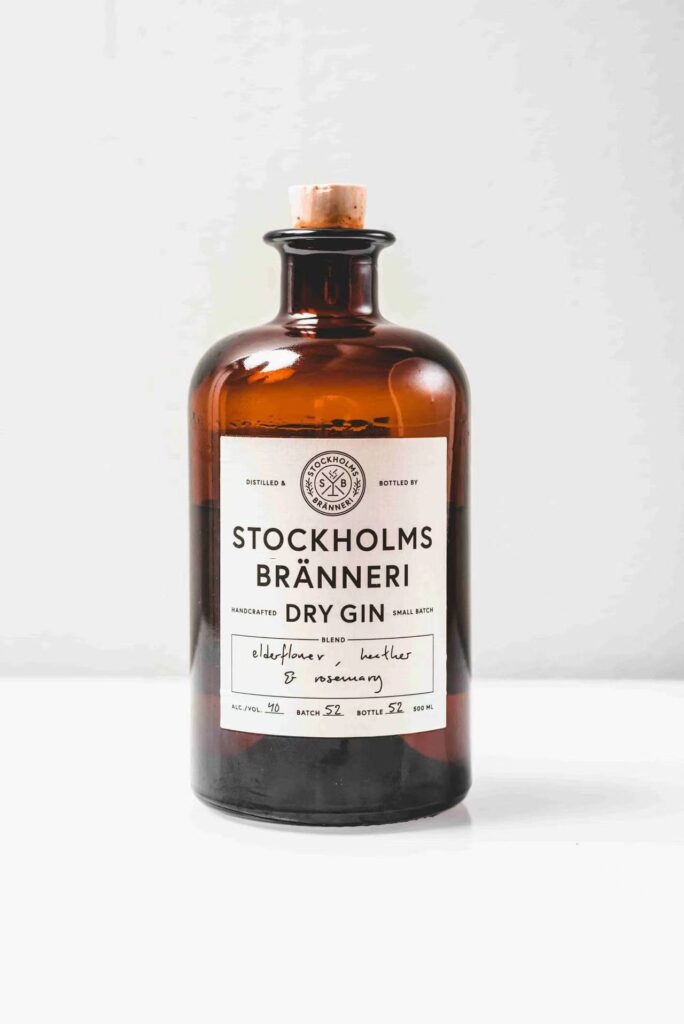

The cork finish is a preferred choice for wine bottles, spirit bottles, and even some glass bottles for oil and vinegar packaging. This finish typically features a smooth neck that accommodates a natural or synthetic cork. The cork not only seals the bottle effectively but also adds a classic aesthetic appeal and an element of ritual to the opening process. Cork finishes are especially popular in products where brand image and consumer experience are closely tied to perceptions of quality and heritage.

▶ Crown Cap Finish

Commonly associated with carbonated beverages, such as beer bottles and soft drink glass bottles, the crown cap finish offers a reliable seal that maintains carbonation and freshness. The design includes a crimped cap that securely grips the flanged edge of the bottle’s neck, creating an airtight seal. Crown caps are efficient for bottling lines and are cost-effective. It’s an excellent choice for high-volume products. Moreover, with advancements in sealing technology, crown caps have evolved to provide better protection against oxygen ingress, further extending the shelf life of carbonated beverages.

▶ Additional Insights

Each neck finish serves a functional purpose and also contributes to the branding and consumer perception. The choice of neck finish can influence the overall packaging design. When selecting a neck finish for a product, we need to consider the technical compatibility and functionality and the consumer’s expectations. The right neck finish can significantly enhance product appeal, and encourage consumer engagement. And ultimately contribute to brand loyalty and product success.

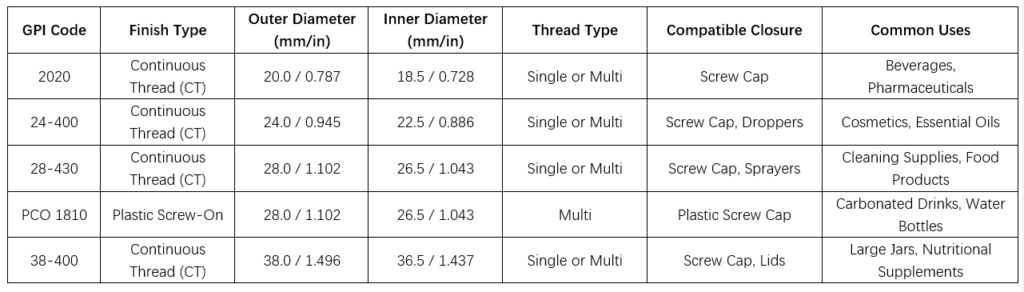

Section 3 Standard Bottle Neck Finish Dimensions Chart Concept Reference

Note:

○ GPI Code: Represents the specific glass packaging institute code.

○ Finish Type: Type of neck finish, e.g., Continuous Thread (CT), Lug, etc.

○ Outer Diameter (mm/in): The external diameter of the neck.

○ Inner Diameter (mm/in): The internal diameter of the neck opening.

○ Thread Type: Indicates whether the finish is designed for a single or multi-turn closure.

○ Compatible Closure: Types of closures that fit the neck finish.

○ Common Uses: Typical products or industries using this neck finish.

Section 4 How to Choose the Right Neck Finish

Choosing the right neck finish for your glass bottles is a critical decision that impacts not just the functionality and integrity of your product, but also its market appeal and user experience. Here are a part of the key factors to consider when selecting the right neck finish:

○ Product Compatibility: Ensure the material of both the bottle and the closure are compatible with your product to prevent degradation or contamination. Consider the viscosity of the product and how easily it pours from the bottle. Certain neck finishes are better suited for thick liquids, while others are ideal for thin, easily pourable substances.

○ Consumer Convenience: Think about how the consumer will interact with the product. Easy-to-open closures like screw caps may be preferred for everyday products, while cork finishes can add a sense of occasion to premium products.

○ Seal Integrity: The neck finish and closure must form a tight seal to prevent leaks, especially for liquid products or those sensitive to air exposure.

○ Aesthetic Appeal: The neck finish should align with your brand’s image and product positioning. A luxurious product might benefit from the traditional appeal of a cork, while a modern, utilitarian product might lean towards a screw cap.

○ Cost Considerations: The cost of equipment to apply the closures (capping machines, corkers) and the closures themselves can vary widely. Some neck finishes and closures can be applied more quickly and easily, affecting your production speed and labor costs.

Partner with Smilebottles

At our Smilebottles, we offer an extensive selection of glass containers and packaging solutions, featuring a variety of neck finishes to cater to your diverse product requirements. Our comprehensive range ensures that you can find the perfect match for your specific needs. Whether you’re looking for a particular seal integrity, aesthetic appeal, or functional design. For businesses seeking quality and reliability, we invite you to explore our wholesale glass bottles and glass jars in bulk. Get in touch with us to discover how our products can elevate your offerings!