Table of Contents

ToggleAuthor: SmileBottles Editorial Team

Estimated Reading Time: About 15 Minutes

That’s what this page is for. We’re going to go through every part of a bottle, tell you what it’s called, what it does, and why it matters to your business. No textbook language. Just the stuff that actually helps you buy smarter.

At Smilebottles, we manufacture glass containers — bottles and jars — for food, beverage, cosmetic, and pharmaceutical companies. We’ve been doing this long enough to know that most ordering mistakes come down to one thing: the buyer and the manufacturer weren’t using the same vocabulary. So let’s fix that.

What Is Bottle Anatomy and Why Should You Bother Learning It?

Think of it this way. You wouldn’t order a car engine without knowing the difference between a piston and a crankshaft. Same logic applies here.

The anatomy of a bottle is just a fancy way of saying “all the different sections of a glass bottle and what they’re called.” When you understand the bottle parts, you can:

Tell your supplier exactly what you need without sending ten reference photos:Avoid ordering the wrong caps for bottle closures (this happens constantly). Spot quality problems during inspection because you know where to look. Compare quotes from different manufacturers on equal terms

Whether you’re sourcing a simple jar for honey or a custom spirit bottle with a heavy base, the terminology is universal. Glass factories in China, Europe, and the Americas all use these same terms.

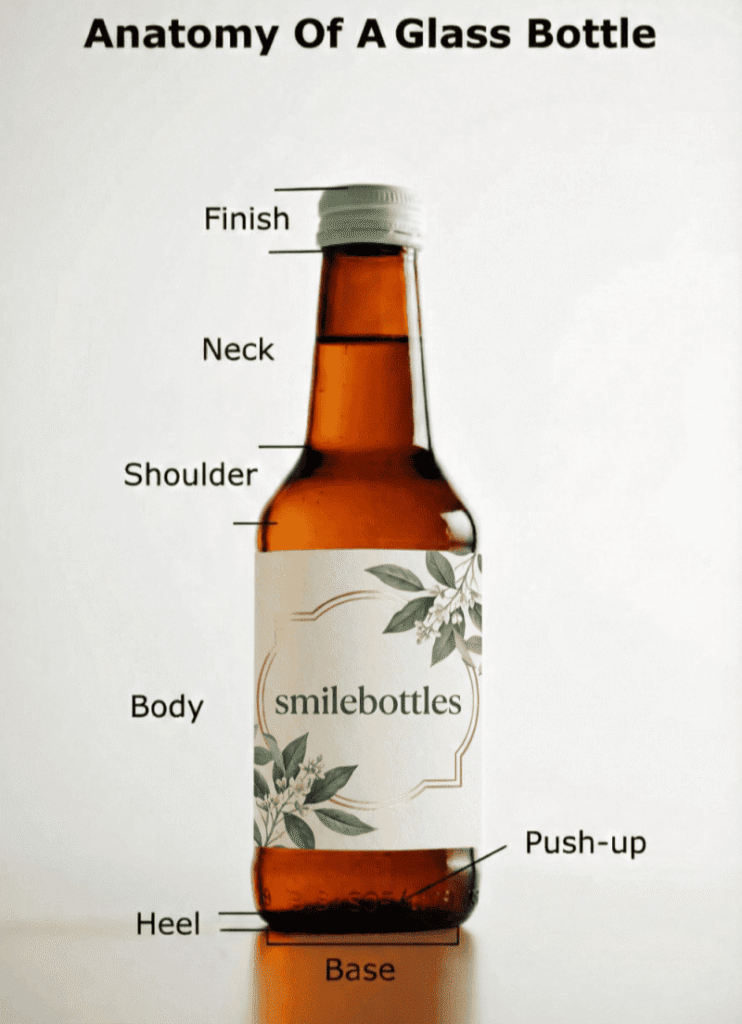

The Glass Bottle Diagram: Every Part, Top to Bottom

We’ll start at the top of the bottle and work down. Grab a bottle off your desk if you have one — it helps to look at the real thing while you read.

1. The Mouth

The mouth is the opening at the top. That’s it. Nothing complicated.

But the size of the mouth matters a lot. A narrow mouth (say, 18mm) works for wine and spirits — you pour from it. A wide mouth (63mm or bigger) turns the container into a jar, and you scoop from it.

If you’re filling something thick like tomato paste, you want a wide mouth so the filling nozzle fits inside and the product doesn’t splash everywhere. If you’re filling water, a narrow mouth is fine.

Don’t mix up “mouth” and “finish.” People do this all the time. The mouth is just the hole. The finish is the whole engineered top section. More on that next.

2. The Finish

This is the single most important thing to get right on your order. The finish is the entire top portion of the bottle — the sealing surface, the threads (if there are any), and the transfer bead at the bottom. Why is it called the “finish”? Old glassblowers used to make the body first and “finish” the top last by hand. The name stuck, even though machines do everything now.

Sealing Surface

The very top rim. This is where the cap of a bottle or cork physically touches the glass to create a seal. If this surface has even a small chip or wave, your product leaks. For carbonated drinks, a bad sealing surface means flat soda and angry customers.

Threads

If you’re using screw-on bottle caps and lids, the finish has spiral ridges molded into the glass. These follow industry standards. In North America, it’s the GPI system. A finish labeled “28-400” means 28mm across, 400-series thread pattern.

Here’s the thing that trips people up: you can’t put a 28-410 cap on a 28-400 bottle. The diameter is the same, but the thread pattern is different. It’ll cross-thread or just sit there loose. When you order bottles with caps from us, we match them. When you source caps separately, double-check the thread spec. Seriously.

Transfer Bead

A small ridge of glass at the very bottom of the finish. During manufacturing, this is where the machine grabs the bottle to move it between stations. For you, it’s a landmark — everything above the transfer bead is “the finish.”

Finish Types You’ll Run Into

|

Type |

What It Looks Like |

Used For |

|

Continuous Thread (CT) |

Spiral screw threads |

Juice, water, sauces, most everything |

|

Crown |

Crimped metal ring |

Beer, soda |

|

Cork |

Smooth, no threads |

Wine, some spirits |

|

ROPP |

Smooth, aluminum cap rolls on |

Wine, olive oil, spirits |

|

Lug |

Short interrupted threads |

Jars — pickles, jam, salsa |

|

Swing Top |

Wire bail + ceramic stopper |

Craft beer, decorative bottles |

3. The Neck

The neck connects the finish to the shoulder. It’s the narrow tube you wrap your hand around when you pour.

In the parts of a wine bottle, the neck is long. That’s partly tradition, partly function — a long neck shows off the wine’s color and gives the server something to hold. For a stocky hot sauce bottle, the neck is stubby. For a tall olive oil bottle (called a “Dorica”), the neck is long and thin.

The neck is also the weakest spot on the bottle. It’s where the glass is thinnest. During shipping, if bottles knock together, the neck breaks first. Good case packaging with dividers protects against this.

4. The Shoulder

The shoulder is where the bottle widens from the neck into the body. It’s a transition zone, and it does more work than you’d think.

For carbonated beverages, the shoulder shape affects how internal pressure spreads through the glass. A gentle slope (like a Burgundy wine bottle) distributes pressure evenly. A sharp, square shoulder (like a Bordeaux) looks bold on a shelf but creates stress points in the glass. The shoulder on a Bordeaux also catches sediment when you pour wine. That’s not an accident — it’s a design choice that’s been around for centuries.

5. The Body

The body is the main section. It holds your product and carries your brand. When people talk about bottle shape names, they’re mostly describing the body:

Boston Round — the round, no-nonsense bottle you see in pharmacies and labs

French Square — square body, saves shelf space, common for syrups

Flask — flat and wide, fits in a pocket, used for spirits

Bordeaux — straight sides, high shoulders, the classic wine shape

Burgundy — wider body, sloped shoulders, also wine

The Label Panel

Somewhere on the body, there’s a smooth area meant for your label. This is the label panel. If you’re using stick-on labels, this panel needs to be flat or consistently curved — otherwise the label wrinkles and bubbles. If you’re using shrink sleeves, the shape matters less because the plastic conforms to the glass.

We can also skip labels entirely and screen-print, emboss, or frost the body directly. Depends on your budget and your brand.

6. The Heel

The heel is the curved bit where the body meets the base. You probably never look at it, but your filling line cares about it a lot.

Bottles travel on conveyors. They bump into each other hundreds of times during a single production run. The heel absorbs most of that contact. If the glass is too thin here, you get chips. Chips turn into cracks. Cracks turn into broken glass on your filling line, and then you’re shutting down for cleanup.

A well-designed heel is thick enough to handle the abuse and curved enough to guide the bottle smoothly into case dividers.

7. The Push-Up (Punt)

Flip a wine bottle over. See that dome pushing up into the bottom? That’s the push-up, or punt.

People ask about this constantly. “Why is there a dent in the bottom of my wine bottle?” Here’s why:

Pressure. Champagne and sparkling wine bottles hold serious internal pressure — around 6 atmospheres. The dome shape is structurally stronger than a flat bottom, same reason bridges use arches.

Sediment. In aged reds, dead yeast and tannin particles settle out over time. The ring around the punt traps that sediment so it doesn’t pour into your glass.

Feel. A deep punt makes the bottle heavier in your hand. It feels expensive. Wineries and spirit brands use this deliberately.

Not every bottle has a punt. Most jar designs have flat bottoms. Small containers for essential oil bottle parts don’t need one either — they’re too small to benefit from the structural advantage.

8. The Glass Bottle Base

The base is the very bottom. It sits on the shelf, the table, the conveyor. If it’s not flat, the bottle rocks. A rocking bottle is a defective bottle.

Look at the base closely and you’ll see tiny raised dots or a rough texture. That’s called stippling. It’s not decorative — it reduces the contact area between the hot glass and the conveyor belt during manufacturing, which prevents thermal cracking. You’ll also see mold numbers and sometimes the factory’s mark stamped into the glass.

For premium spirits, the base is often extra thick — sometimes called a “slug.” It adds weight. When a customer picks up the bottle, that heft says “this is the good stuff.” It’s marketing through physics.

Closures: Bottle Caps, Lids, Corks, and Everything Else

A bottle without a closure is just a glass tube. The closure world is its own universe, so here’s what you need to know.

Screw Caps

The standard bottle cap. Plastic or metal, with a liner inside that creates the actual seal. The cap is just the shell — the liner does the real work. Different products need different liners. Acidic juice eats through some liner materials. Essential oils dissolve others. Tell us what you’re filling and we’ll match the liner.

Lug Caps

Metal twist-off caps for jars. Instead of continuous threads, they grab onto small glass lugs on the finish. You twist a quarter turn and they’re off. Every jar with glass walls in your kitchen pantry probably uses one of these.

Corks and Stoppers

Natural cork, synthetic cork, or composite. For spirits, there’s the “bar top” — a cork with a wooden or plastic head shaped like a T. Some people call these a bottle topper or a wine bottle topper. In the tequila world, the topper might be a hand-carved figurine. We’ve seen everything.

Dropper with Cap

If you’re in cosmetics, CBD, or pharmaceuticals, you know this one. It’s a glass pipette attached to a rubber bulb, housed inside a threaded collar. The whole assembly screws onto the bottle. We supply these pre-assembled so they’re ready to go on your line.

Over-Caps and Decorative Covers

Perfume bottles usually have a crimp-on pump as the functional closure. But on top of that sits a decorative cover — the cologne cap. It’s purely for looks, but it’s what the customer sees first. Some people in the trade call it a bottle hat or bottle cap hat because it sits on top like, well, a hat. In niche packaging circles you might even hear hat with bottles used to describe these oversized decorative toppers. Whatever the name, if you can sketch it, we can make it.

Bottle Lid or Cap — What’s the Difference?

Honestly? In everyday conversation, nothing. “Lid” and “cap” are used interchangeably. Technically, a “lid” implies a flat cover (like on a jar) and a “cap” implies something that wraps around the finish (like a screw cap). But nobody will correct you either way. A lid bottle setup and a cap bottles setup can mean the same thing depending on who you’re talking to.

Sourcing Closures

Buyers ask us all the time: “Where can I buy bottle tops?” Our honest advice: buy them from whoever makes your bottles. When you get bottles with caps from the same supplier, the fit is guaranteed. We test every bottle cap combination before shipping.

If you’re sourcing bottle tops for sale from a separate vendor, you need the exact finish specification — diameter, thread style, and height. Get any of those wrong, and you’re stuck with boxes of bottle caps and lids that don’t fit anything.

Jars vs. Bottles: What’s Actually Different?

A jar and a bottle are both glass containers. The difference is the opening.

Glass Bottle: narrow neck, designed for pouring

Glass Jar: wide mouth, designed for scooping or reaching inside

A glass jar with a glass top — like those clamp-lid storage jars you see in kitchens — uses a rubber gasket and wire bail to seal. That’s a completely different mechanism from a threaded bottle cap.

The parts of glass jars are simpler than bottles. There’s usually no distinct neck or shoulder. It’s basically: mouth, body, base. The finish on a jar is wider and uses lug threads or a bail mechanism instead of continuous screw threads.

If your product is thick (body butter, candle wax, jam), go with a jar. If it pours (juice, oil, vinegar), go with a bottle.

Glassware vs. Glass Packaging — Not the Same Thing

We get visitors who land on our site looking for parts of a glassware set — wine glasses, tumblers, that sort of thing. Different industry entirely, but worth clearing up.

Parts of a wine glass (the thing you drink from): Bowl, Stem, Foot.

Parts of the wine bottle (the thing you ship your wine in): Finish, Neck, Shoulder, Body, Punt, Base.

Smilebottles makes the packaging — the bottles and jars. We don’t make stemware or drinkware.

And while we’re at it: a bottle cup usually refers to a measuring cup that clips onto the top of a medicine or detergent bottle. It doubles as the cap. If you need these for your product, we can source them as part of your packaging kit.

How Design Choices Affect Your Product

Now that you know the parts of the bottle, here’s how those parts connect to real-world performance.

Carbonation: Sparkling drinks push outward on the glass from the inside. You need thick walls, a deep punt, and a crown or swing-top finish. Thin glass with a flat base and a screw cap? That’s a time bomb.

Hot-Fill: If you’re pouring hot liquid into the bottle to sterilize it (common for juice and sauces), the glass needs to handle thermal shock. The heel and base are most vulnerable because the glass is thickest there and cools unevenly. We anneal every bottle to relieve internal stress, but you should still tell us if you’re hot-filling so we can adjust the glass distribution.

Shipping: Heavier bottles survive rough handling better, but they cost more to ship. There’s always a trade-off. If you’re shipping domestically by truck, you can go lighter. If you’re shipping overseas in a container that’ll sit in tropical heat for three weeks, go heavier.

Filling Line Speed: Your bottle has to run on automated equipment. That means the finish dimensions need to be dead consistent (for the capping machine), and the base needs to be flat (for the conveyor). A bottle that wobbles on the line slows everything down and causes jams.

Why Smilebottles is your best partner for glass bottles?

Custom molds. If the standard bottle shape names don’t work for your brand, we engineer a new one. You own the mold.

Closure matching. We supply bottle caps and lids, corks, droppers, pumps, and specialty closures — all tested against your bottle’s finish.

Decoration. Screen printing, frosting, spray coating, embossing. Done in our facility, not farmed out.

Quality control. We inspect sealing surfaces, dimensions, and thermal resistance on every production run.

Flexibility. Whether you need 5,000 pieces or 5 million, we handle it.

We work with beverage brands, cosmetic companies, pharmaceutical packagers, and food producers. If you’re looking for bottles with caps that actually fit, glass that doesn’t crack on the filling line, and a supplier who picks up the phone when there’s a problem — that’s us.

FAQ Frequently Asked Questions About Glass Bottles

Q1:What’s the difference between the mouth and the finish?

A1:The mouth is the hole. The finish is the entire top section — sealing surface, threads, transfer bead. When you’re ordering bottle caps, you specify the finish, not the mouth.

Q2:Why do wine bottles have that dent in the bottom?

A2:That’s the punt. It handles pressure in sparkling wines, collects sediment in reds, and makes the bottle feel heavier and more premium.

Q3:What’s the strongest part of a glass bottle?

A3:The heel and base. The glass is thickest there.

Q4:Can I order just the bottle cap without the bottle?

A4:Yes, but you need the exact finish spec. A bottle topper that doesn’t match the thread pattern is scrap.

Q5:What are cap bottles?

A5:Just bottles sold with matching caps. When you buy cap bottles from us, the closure is tested and guaranteed to fit.

Q6:What is a bottle cap hat?

A6:Informal term for a tamper-evident band or decorative over-cap that sits on top of the main closure.

Final Thoughts

Every part of a glass bottle is there for a reason. The finish seals your product. The shoulder handles pressure. The body carries your brand. The base keeps it standing. When you understand the glass bottle diagram and can name each section, you stop guessing and start specifying. That’s how you avoid expensive mistakes. That’s how you get exactly what you need on the first order. Got a project in mind? Send Smilebottles your specs — or even just a rough sketch — and we’ll take it from there.