Is it better to tighten the lid of glass containers as much as possible? Actually not.

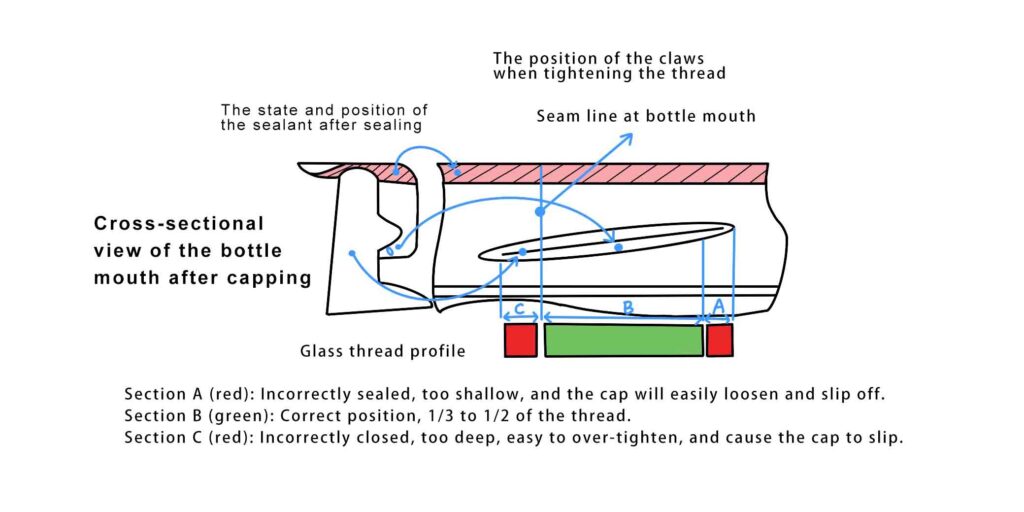

In many people’s perception, the tighter the lid is, the better. The perception is wrong. Let’s look at the picture below, the sealing principle diagram of the claw-type screw-open lid.

The left side of the picture is a cross-sectional view of the bottle mouth after capping. We can see that it is the sealant inside the cap that plays the sealing role, not the claws. The claws tighten the thread so that the sealant tightly adheres to the bottle mouth to form a seal. If the glass bottle mouth is defective, such as cracks, crossing the bottle mouth line, the bottle mouth plane is not enough, or the corrugated bottle mouth, no matter how good the lid is, it will still penetrate down. Such as oil leakage or the safety button cannot suck.

▶ If the mouth of the glass bottle is flawless and the lid is tightened too tightly, it will often cause the claws to dig into the thread too deeply.

Such as position C in the picture on the right, or even over-tightening. At this time, the claws will often turn out, and the anti-corrosion on the claws will The rust coating was also damaged. If the claws are everted, they will not be able to fasten the thread. This will result in insufficient pulling force to make the rubber surface and the bottle mouth plane fit tightly. Therefore, the sealing effect will be greatly reduced. And when the rust coating is destroyed, it is more likely to cause the cover to rust and affect food safety. If the claws are screwed into the C position in the figure, it will also cause the capping machine to have excessive torque. The belt of the capping machine will be easily fatigued and strained. The capping machine and its accessories will be easily damaged and must be shut down frequently for inspection.

▶ If the mouth of the glass bottle is not defective and the cap is too loose.

Then the claws will be too shallow into the thread, as shown in position A in the picture on the right. At this time, the pull-down force exerted by the claw fastening thread on the cover is not enough to make the rubber surface tightly fit the bottle mouth. The sealing is not tight enough, which often leads to leakage. If the thread of the lid is too shallow, it will easily loosen and slide off. Especially during transportation after filling. During collision and extrusion, the lid will easily loosen and slide off. And the sealing effect will not be effective or even poor.

▶ Ideal Position for Capping.

Through the above analysis, we can realize that the ideal position for capping is position B. That is the position where the cap is screwed into the thread about 1/2, which will not cause the claws to evert out. But also allow the claws to generate enough pulling force to pull the bottle mouth together. The rubber surfaces inside the cover fit tightly together to form a better sealing effect.

Through the above learning, we can understand that the claw-type unscrew cap is not tightened as tightly as possible. If you’re interested in more knowledge about glass containers and accessories, welcome to check our blogs!