Foil Hot Stamping is a remarkable technique that combines age-old craftsmanship with modern technology to elevate the appearance of products across various industries. Originating from ancient practices of adorning luxurious items, Foil Hot Stamping has evolved into a sophisticated process, enhancing everything from elegant packaging to bespoke stationery. But how the technique was invented? How do people make it realized in modern mass production? What are the applications? Let’s learn more about the secrets of Foil Hot Stamping!

Section 1 The Origins and Evolution of Foil Hot Stamping

Ancient Beginnings

The concept of applying a metallic finish to materials dates back to ancient times. The earliest forms of foil stamping can be traced back to the Egyptians, who were known to beat gold into thin sheets and use them to decorate mummies and coffins. However, this was a rudimentary form and not directly related to the modern process of hot stamping.

Middle Ages and Renaissance

The method saw significant refinement during the Middle Ages and the Renaissance, particularly in the realm of bookbinding. During this era, bookbinders began using gold leaf to embellish the leather covers and spines of books. They would manually inscribe designs or letters into the book covers and then place gold leaf over these designs. Using simple hand tools, they would then apply heat and pressure to transfer the gold leaf onto the book covers.

19th Century: The Advent of Modern Foil Stamping

The 19th century marked a turning point in the evolution of foil stamping. This period saw the transition from manual labor to mechanization. As the Industrial Revolution progressed, new machines were developed that could automate the stamping process. The key development was the creation of a die or stamp that could be heated and used to press a design onto a surface.

The Introduction of Foil

Initially, gold leaf was used for stamping, which was both expensive and delicate. The breakthrough came with the development of foil, a thin film coated with a layer of metal. This foil could be produced in large quantities and was more durable and versatile than gold leaf. The introduction of foil made the stamping process more efficient and cost-effective, allowing for wider use in various industries.

20th Century to Present

In the 20th century, foil hot stamping continued to evolve with advancements in technology and materials. The range of foils expanded, including various colors and finishes, allowing for more creative and diverse applications. The machinery used for hot stamping became more sophisticated, with the ability to apply consistent heat and pressure, ensuring high-quality results.

Today, foil hot stamping is a highly refined process used in numerous industries, from packaging and labeling to bookbinding and fashion. It’s valued for its ability to add a touch of luxury and distinction to products, and its applications continue to grow with ongoing technological advancements.

Section 2 The Modern Foil Hot Stamping Technique

Design Creation and Die-making

The process begins with the creation of a design, which is the first critical step. This design, often created using graphic design software, is a detailed representation of what will be stamped onto the product. Once the design is finalized, it is used to manufacture a metal stamp or die. This die is usually made of brass, copper, or magnesium and is crafted through engraving or etching to accurately represent the design details.

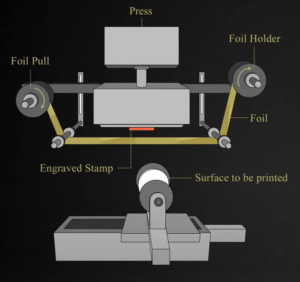

Preparing the Stamping Machine

The stamping machine plays a crucial role in the hot stamping process. It is equipped with a heating element that warms up the die. The temperature is carefully controlled and varies depending on the type of foil and substrate used. The machine also features a mechanism to apply pressure during the stamping process.

Foil Selection and Positioning

A wide range of foils is available, varying in color, finish, and material composition. The chosen foil is placed over the substrate (the material to be stamped), with the colored or metallic side facing up.

Stamping

Once the machine reaches the desired temperature, the substrate with the foil on top is placed under the die. The machine then applies pressure, pressing the heated die onto the foil and substrate. The heat and pressure cause the foil’s design layer to bond to the substrate. The areas of the foil where the design is not present do not stick to the substrate and remain intact.

Removal of Excess Foil

After stamping, the substrate is removed from the machine. The excess foil, which did not adhere to the substrate, is peeled away, leaving only the design transferred onto the substrate.

Quality Inspection and Finishing Touches

The final step involves a thorough inspection of the stamped product to ensure quality and accuracy. Any necessary finishing touches are applied to enhance the appearance or protect the stamped design.

The modern Foil Hot Stamping process is a blend of art and precision engineering, resulting in stunning and durable designs. This technique is widely used for decorating various items, from packaging and labels to book covers and promotional products, offering an elegant and high-quality finish.

Section 3 Applications of Foil Hot Stamping

Foil hot stamping is versatile and can be applied to a myriad of products:

○Packaging: Adds a premium look to product packaging, especially for cosmetics, wines, and luxury goods.

○Stationery: Used in business cards, invitations, and certificates to provide a touch of sophistication.

○Books and Publications: Enhances book covers, giving them a distinctive, high-quality appearance.

○Leather Goods: Often used in branding and personalizing leather products like wallets and handbags.

○Plastic and Glass Products: Can be used to decorate bottles, jars, and various plastic items, adhering well to different surfaces.

Section 4 Why Customizing Glass Bottles with Foil Hot Stamping?

Foil Hot Stamping is indeed a popular and effective technique for custom glass bottles and jars. This method is highly valued in the glass bottle industry for several key reasons:

Premium Appearance: Foil Hot Stamping adds a luxurious and high-end look to glass bottles. This is particularly important for products like bespoke glass spirits bottles, empty wine bottles, premium perfume bottles, and high-end glass cosmetic container products. Where the packaging significantly influences customer perception and brand value.

Durability: The process ensures that the designs or text applied to the bottles are durable and resistant to wear and tear. This is crucial for custom glass bottles, which often undergo handling and transportation.

Versatility in Design: It allows for a wide range of design possibilities, from intricate patterns to bold branding elements. The variety of foil colors and finishes (like matte, glossy, and metallic) offers vast creative potential to match brand identities or product themes.

Eco-Friendly Option: In comparison to other decorating techniques, Foil Hot Stamping can be more environmentally friendly. The foils used are often thin and require less material than other forms of glass bottle decoration.

Efficiency: The process is relatively fast and can be automated, making it suitable for both small custom batches and large-scale production. This efficiency is vital for businesses looking to balance quality with productivity.

Given these advantages, Foil Hot Stamping is an excellent choice for customizing glass bottles, enhancing both the aesthetic appeal and the perceived value of the products they contain. It aligns well with the needs of businesses in the food, beverage, beauty, and luxury goods sectors that seek to distinguish their products through distinctive and elegant packaging.

Custom Foil Hot Stamping at Smilebottles

At Smilebottles, we specialize in transforming glass bottles and jars into works of art through our expert Foil Hot Stamping service. Whether you’re in the wine, spirits, food, beverage, or beauty industry, our custom stamping process offers an elegant and sophisticated touch to your packaging.

Our state-of-the-art Foil Hot Stamping technique ensures high-quality, durable, and visually stunning results, perfectly tailored to your brand’s identity. With a range of designs and finishes, we promise packaging that not only captures attention but also elevates the perceived value of your products.

Looking to make a lasting impression with your packaging? Contact us at Smilebottles for bespoke glass bottles and jars that truly stand out. Let us help you showcase your brand in its best light.