Borosilicate glass is a marvel of modern materials science. It holds a special place in the pantheon of glass due to its unique properties and versatile applications. But what exactly makes it stand apart from traditional glass? In our latest blog, we dive deep into the world of borosilicate glass, answering 15 pivotal questions that unveil its secrets. From its remarkable resistance to thermal shock and chemical corrosion to its widespread use across industries, we’ll explore the intricacies that make borosilicate containers a material of choice for professionals and consumers alike. Join us and reveal the reasons behind its growing popularity.

Table of Contents

ToggleCONTENTS LIST

Q1: What is borosilicate and how is it made?

Q2: What are the main uses of borosilicate glass?

Q3: How does borosilicate glass compare to regular glass?

Q4: Are borosilicate containers safe for food and beverage storage?

Q5: Can borosilicate glassware be used in the microwave and oven?

Q6: What makes borosilicate glass resistant to thermal shock?

Q7: Are borosilicate containers better for the environment?

Q8: How can you tell if a glass is borosilicate?

Q9: Can borosilicate glass be recycled?

Q10: What industries benefit most from using borosilicate glassware?

Q11: Is borosilicate glass more expensive than other types of glass?

Q12: What are the limitations of using borosilicate glass?

Q13: How do you clean and care for borosilicate glassware?

Q14: Can borosilicate glass break or shatter?

Q15: What are the differences between borosilicate glass and tempered glass?

Q1: What is borosilicate and how is it made?

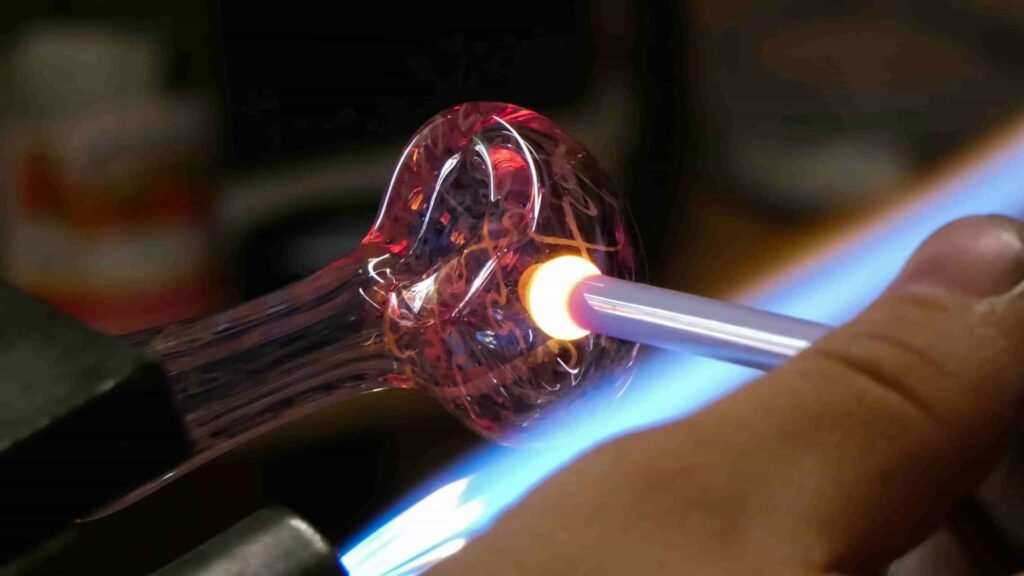

Borosilicate is a type of glass that stands out due to its unique composition and properties. It is made by blending silica and boron trioxide at very high temperatures. Creating a glass that is much more resistant to thermal shock and chemical corrosion than ordinary soda-lime glass. The process begins with the careful selection of raw materials, which are then melted together in a furnace at temperatures reaching up to 1700°C (3090°F). This fusion results in a clear, durable glass that has a low coefficient of thermal expansion. Meaning it does not expand or contract significantly with temperature changes. This characteristic makes borosilicate glass ideal for applications where sudden temperature variations are common. Such as in laboratory equipment, cookware, and certain types of lighting and industrial applications. The production of borosilicate glassware requires precise control and expertise to ensure the final product meets the high standards of quality and performance expected of this advanced material.

Q2: What are the main uses of borosilicate glass?

Borosilicate, renowned for its exceptional durability and resistance to thermal shock and chemical attack, finds its place in a wide array of applications across various industries. Its main uses include:

○ Laboratory Equipment: Its resistance to chemicals and sudden temperature changes makes it ideal for laboratory glassware, such as beakers, test tubes, Petri dishes, and flasks.

○ Cookware and Kitchenware: Borosilicate glass is used to manufacture oven-safe cookware, including baking dishes, casserole pans, and measuring cups, due to its ability to withstand high temperatures without cracking.

○ Pharmaceutical Packaging: Vials, ampoules, and syringes in borosilicate glass are preferred for storing medications because it does not react with the contents, ensuring drug purity and safety.

○ Optical Applications: Its clear and durable nature makes it suitable for lenses, mirrors, and prisms in telescopes and cameras, where precision and reliability are crucial.

○ Lighting: Borosilicate glass is used in lightbulb production and as protective covers for outdoor and industrial lighting fixtures. Owing to its heat resistance and durability.

○ Solar Panels: Some types of solar panels use borosilicate glass as a protective layer because of its strength and ability to transmit light efficiently.

○ Beverage and Food Storage: Bottles and containers for acidic beverages, oils, and other food items benefit from their non-reactive properties, preserving taste and quality.

○ Art and Decor: Its aesthetic appeal and malleability when heated make it a popular choice for glass art, ornaments, and decorative items.

These diverse applications underscore the material’s versatility. Proving borosilicate glass is an indispensable resource in both everyday items and specialized equipment.

Q3: How does borosilicate glass compare to regular glass?

Borosilicate stands out from regular glass mainly due to its superior resistance to thermal shock and chemical corrosion. It can withstand sudden temperature changes without cracking, making it ideal for applications requiring exposure to varying temperatures. Additionally, borosilicate glass containers are more chemically stable, resisting degradation and ensuring the purity of their contents. Which is crucial for laboratory use, food storage, and pharmaceutical packaging. While both types of glass are durable and recyclable, borosilicate glass’s enhanced properties come with a higher production cost. Making it more expensive but also more suitable for specialized uses where its unique benefits are essential.

Q4: Are borosilicate containers safe for food and beverage storage?

Yes, borosilicate glassware is safe for food and beverage storage. Its chemical stability and inertness ensure that it does not react with the contents it holds. Maintaining the purity and taste of food and beverages. Unlike some plastics and other materials, borosilicate does not leach chemicals into its contents, even when exposed to extreme temperatures, making it an excellent choice for storing everything from hot beverages to acidic foods.

Q5: Can borosilicate glassware be used in the microwave and oven?

Yes, glassware in borosilicate is well-suited for use in both the microwave and oven. Its low coefficient of thermal expansion means it can handle significant temperature changes without cracking. It’s ideal for heating food in the microwave or cooking and baking in the oven. This resistance to thermal shock allows for direct transfer from the refrigerator to the heating device, adding convenience and versatility to food preparation. However, it’s always recommended to check the manufacturer’s guidelines. Certain designs or additional features of borosilicate glassware might affect its suitability for use in high-temperature environments.

Q6: What makes borosilicate glass resistant to thermal shock?

Borosilicate glass’s resistance to thermal shock is primarily due to its unique chemical composition, which includes silica and boron trioxide. This composition results in a material with a very low coefficient of thermal expansion. In simpler terms, borosilicate containers do not expand or contract significantly with temperature changes, unlike regular glass. This stability under thermal stress means it can withstand sudden temperature shifts—from hot to cold and vice versa—without cracking or shattering.

Q7: Are borosilicate containers better for the environment?

Yes, borosilicate containers are generally considered better for the environment for several reasons:

○ Durability: Borosilicate glass’s enhanced durability means it can be used and reused for longer periods compared to regular glass or plastic containers, reducing waste and the need for frequent replacements.

○ Recyclability: Like other types of glass, borosilicate bottles and jars are fully recyclable. Its ability to be melted down and reshaped into new products without losing purity or quality supports circular economy principles.

○ Chemical Stability: The inert nature of borosilicate ensures that it does not leach harmful chemicals into the environment or require the use of chemical liners that can contribute to pollution.

○ Energy Efficiency in Production: Although producing borosilicate glass requires high temperatures, its longevity and reduced replacement rate potentially offset the initial environmental impact over time.

○ Health and Safety: By providing a safe option for food and beverage storage that does not contaminate contents with harmful chemicals, glass containers of borosilicate reduce the health risks and environmental damage associated with some plastics and other materials.

In summary, the environmental benefits of borosilicate glass containers stem from their long life span, recyclability, and safety, contributing to less waste and pollution over time.

Q8: How can you tell if a glass is borosilicate?

Identifying borosilicate glass can be challenging without specific manufacturer information. Because it looks similar to regular glass. However, there are a few indicators that can suggest glass is borosilicate:

○ Manufacturer’s Markings: Check for any labels or markings from the manufacturer indicating that the product is made from borosilicate glass.

○ Heat Resistance: Borosilicate glass is known for its ability to withstand sudden temperature changes. Products marketed for use in high-temperature environments (like ovenware) are often made of borosilicate.

○ Weight and Thickness: Borosilicate glass tends to be lighter and thinner than soda-lime glass while maintaining strength, due to its superior thermal and chemical resistance properties.

○ Price: Because of its specialized manufacturing process, borosilicate products may be priced higher than similar items made from regular glass.

○ Sound: Borosilicate glass can produce a distinct, more “ping”-like sound compared to the duller thud of soda-lime glass when tapped gently.

If in doubt, the most reliable method to confirm if a glass is borosilicate is to consult the manufacturer’s specifications or product documentation.

Q9: Can borosilicate glass be recycled?

Yes, borosilicate glass can be recycled. However, the recycling process for borosilicate glass differs from that of regular soda-lime glass due to its distinct chemical composition and higher melting point. Because of these differences, borosilicate glass should ideally be recycled separately to ensure the integrity of the recycled material and to prevent contamination of the regular glass recycling stream.

Q10: What industries benefit most from using borosilicate glassware?

Borosilicate glass is highly valued across various industries for its thermal resistance, chemical stability, and durability. The sectors that benefit most from using borosilicate glass include Laboratory and Scientific Research, Pharmaceuticals, Food and Beverage, Cookware and Kitchenware, Lighting Industry, Solar Power, etc.

These industries leverage the unique properties of borosilicate glass to enhance product safety, longevity, and performance, underscoring its versatility and importance across a broad range of applications.

Q11: Is borosilicate glass more expensive than other types of glass?

Yes, borosilicate glass is typically more expensive than other types of glass, such as standard soda-lime glass. This increased cost is attributed to the specialized materials and the higher manufacturing temperatures required to produce borosilicate glass. These factors, combined with the need for specialized equipment and the overall process complexity, contribute to its higher price. However, the superior durability, thermal resistance, and chemical stability of borosilicate glass often make it a cost-effective choice in the long run. Given its extended lifespan and versatility across various applications.

Q12: What are the limitations of using borosilicate glass?

Despite its numerous benefits, borosilicate glass does have some limitations. Its higher cost, compared to standard soda-lime glass, may not fit all budgets, particularly for large-scale or cost-sensitive projects. While it boasts superior thermal resistance and chemical stability, borosilicate glass is more brittle. Making it susceptible to breaking on impact. Additionally, its recycling process is more complex due to its unique composition, posing challenges for standard recycling programs. These factors necessitate careful consideration when choosing borosilicate glass for specific applications, balancing its advanced properties against these constraints.

Q13: How do you clean and care for borosilicate glassware?

Caring for borosilicate glassware involves simple yet effective practices. To clean borosilicate glass containers, we can use warm, soapy water. And a soft sponge or cloth to gently remove any residues or stains. Avoid using abrasive scrubbers or harsh chemicals that will scratch the surface. For tougher stains, soaking the glassware in a mixture of warm water and mild detergent can help loosen debris before washing. Rinse thoroughly with clean water to remove any soap residues. Borosilicate glass is generally dishwasher safe, but check the manufacturer’s instructions to ensure compatibility. To prevent thermal shock, avoid exposing glassware to sudden temperature changes. Such as moving it directly from a hot environment to cold water. With proper care, borosilicate glassware can remain a clear, durable, and reliable part of your kitchen or laboratory for years.

Q14: Can borosilicate glass break or shatter?

Yes, borosilicate containers can break or shatter, despite their reputation for durability and resistance to thermal shock. But it is designed to withstand sudden temperature changes. Borosilicate is less likely to break under thermal stress compared to regular glass. It is not immune to all forms of damage, either. Borosilicate glass can break if subjected to severe impact, excessive force, or if it has pre-existing flaws or damage. It’s also important to note that improper handling. Such as dropping or striking the glassware, can lead to breakage. Therefore, borosilicate glass should also still be handled with care to maintain its integrity.

Q15: What are the differences between borosilicate glass and tempered glass?

Borosilicate glass and tempered glass are both known for their enhanced durability and safety features. But they have distinct properties and are used for different applications. Borosilicate glass is highly resistant to thermal shock and chemical corrosion due to its unique composition. It’s ideal for laboratory equipment, cookware, and high-quality food storage.

Tempered glass, also known as toughened glass, is made by rapidly cooling the exterior of the glass while the interior remains hotter. This process creates a glass that is much stronger than regular glass. If broken, it will shatter into small, blunt pieces that are less likely to cause injury. Tempered glass is commonly used in automotive windows, shower doors, and safety glass in buildings.

The key differences lie in their manufacturing processes and resulting properties. Borosilicate glass offers superior thermal and chemical resistance. Making it suitable for scientific and culinary use. Tempered glass provides enhanced strength and safety, which is ideal for structural and protective applications.