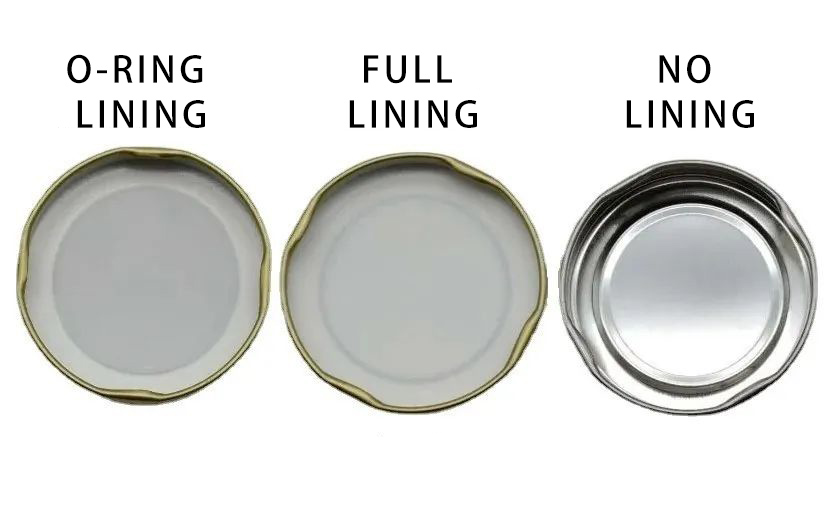

In the world of packaging, the details that go into ensuring product safety, freshness, and quality are paramount. Among these crucial details, the type of lid linings chosen for containers stands out as a key factor in meeting the diverse needs of various products. From the preservation of food items to the storage of industrial goods, the choice of lid lining plays a pivotal role. This blog delves into the intricacies of three main types of lid linings – O-ring lining, full lining, and no lining. We will highlight their unique characteristics, applications, and how they contribute to the overall integrity of packaging solutions.

Table of Contents

ToggleCONTENTS LIST

O-RING LINING

As shown in the picture, the one on the right is an O-ring lining. The sealant is located in the groove on the round edge of the lid. There is no sealant in the middle. This type of lid is the most common and widely used in various types of food packaging. Such as glass sauce jars, honey jars, and glass storage bottles. The O-ring lining fits tightly with the mouth of the glass bottle to form a seal.

FULL LINING

The lid in the middle of the picture is full lining. Even the middle part of the lid is also coated with an oily glue layer. This type of lid is mostly used to seal acidic food and bird’s nest soup products. The main reason is that the pH of acidic products is low. If the cap and bottle do not fit perfectly, the contents in the glass container will be in direct contact with the inside of the lid, which will easily cause rust. And it will affect the taste, hygiene, and safety of the food. Similarly, food like bird’s nest soup contains sulfide, which can easily cause rust if it comes into direct contact with the inside of the cover. Therefore, it is generally recommended to use a cap of full lining. A full-lining cover can block direct contact between the contents and the inside of the cover, reducing the possibility of rust. However, what function of the sealing is the circular edge groove part, which fits the glass bottle mouth to form a seal. As the cover is fully filled with glue, the amount of glue used must be more than that of the ring. So its cost is higher than that of a half-plastic cover.

NO LINING

The lid on the right side of the picture is a lid with no lining. This type of lid is mainly used in industrial products or dried fruit foods that do not have high sealing requirements. The lid can be stuffed with a PE gasket or a heat-sensitive gasket, and the gasket is used for the sealing effect. Because there is no lining, this type of cap has the lowest cost among the above three types.

Smilebottles' Solutions

Selecting the right lid for glass containers is more than just a matter of sealing a container. It’s about ensuring the quality, safety, and longevity of the contents inside. O-ring linings are widely used for food packaging. Full lining can protect the nature of acidic foods and delicate products like bird’s nest soup. No-lining lids are cost-effective and suitable for industrial and dried food products. Each type serves a distinct purpose. Understanding the nuances of these lid linings is crucial for manufacturers, brands, and packaging designers in making informed decisions that align with their product needs and customer expectations. As the packaging industry continues to evolve, the technologies behind lid linings are developing. We, Smilebottles, promise even more tailored and innovative solutions to keep up with the demands of consumers and the marketplace.